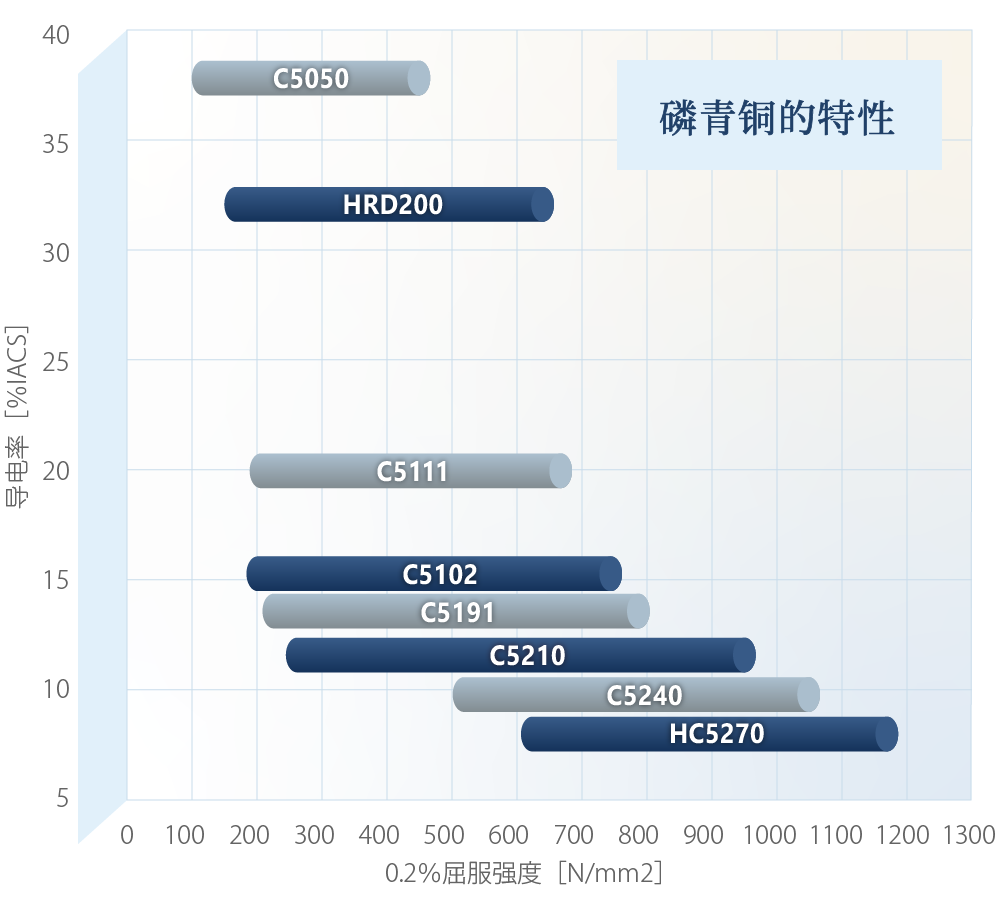

产品简介

磷青铜板及卷材

※如欲了解材料化学成分、机械特性,厚度规格及标准外规格等信息,请联系我们。

物理特性

| 型号 | (单位) | C5050 | HRD200 | C5111 | C5102 | C5191 | C5212 |

|---|---|---|---|---|---|---|---|

| 比重 | - | 8.89 | 8.87 | 8.86 | 8.86 | 8.82 | 8.80 |

| 线膨胀系数 | 10-6 /K | 17.8 | 16.5 | 17.8 | 17.8 | 18.2 | 18.2 |

| 热传导率 | W/m・K | 205 | 152 | 84 | 71 | 67 | 63 |

| 导电率 | %IACS | 38 | 32 | 20 | 15 | 14 | 12 |

| 比热 | J/Kg・K | 377 | 377 | 377 | 377 | 375 | 377 |

| 纵向弹性系数(张力) | kN/m㎡ | 118 | 122 | 110 | 110 | 115 | 110 |

化学成分

| 型号 | 化学成分(%) | |||||

|---|---|---|---|---|---|---|

| Sn | P | Fe | Pb | Zn | Cu+Sn+P | |

| C5050 | 1.0~1.7 | ≦ 0.15 | ≦ 0.10 | ≦ 0.02 | ≦ 0.20 | ≧ 99.5 | HRD200 | 1.7~2.3 | ≦ 0.15 |

| C5111 | 3.5~4.5 | 0.03~0.35 | ||||

| C5102 | 4.5~5.5 | |||||

| C5191 | 5.5~7.0 | |||||

| C5212 | 7.0~9.0 | |||||

机械特性

| 型号 | 材质 | 抗拉测试 | 硬度测试 | |||

|---|---|---|---|---|---|---|

| 厚度 ㎜ |

抗拉强度 N/m㎡ |

延展率 % |

厚度 ㎜ |

硬度 HV※1 |

||

| C5050 | O | ≧ 0.10 ,≦ 5.0 | ≧ 240 | ≧ 40 | - | - |

| 1/4H | ≧ 0.10 ,≦ 5.0 | 240~330 | ≧ 30 | ≧ 0.15 ,≦ 5.0 | 60~120 | |

| 1/2H | ≧ 0.10 ,≦ 5.0 | 330~450 | ≧ 10 | ≧ 0.10 ,≦ 5.0 | 90~155 | |

| H | ≧ 0.10 ,≦ 5.0 | 390~500 | ≧ 3 | ≧ 0.10 ,≦ 5.0 | 120~165 | |

| EH | ≧ 0.10 ,≦ 5.0 | ≧ 460 | - | ≧ 0.05 ,≦ 5.0 | ≧ 140 | |

| HRD200 | O | ≧ 0.10 ,≦ 5.0 | ≧ 300 | ≧ 30 | ≧ 0.10 ,≦ 5.0 | 70~115 |

| 1/2H | ≧ 0.10 ,≦ 5.0 | 400~500 | ≧ 10 | ≧ 0.10 ,≦ 5.0 | 125~165 | |

| H | ≧ 0.10 ,≦ 5.0 | 450~550 | ≧ 5 | ≧ 0.10 ,≦ 5.0 | 150~185 | |

| EH | ≧ 0.10 ,≦ 5.0 | 500~600 | ≧ 2 | ≧ 0.10 ,≦ 5.0 | 175~205 | |

| SH | ≧ 0.10 ,≦ 5.0 | 600~700 | - | ≧ 0.10 ,≦ 5.0 | 185~215 | |

| C5111 | O | ≧ 0.10 ,≦ 5.0 | ≧ 295 | ≧ 38 | - | - |

| 1/4H | ≧ 0.10 ,≦ 5.0 | 345~440 | ≧ 25 | ≧ 0.15 ,≦ 5.0 | 80~150 | |

| 1/2H | ≧ 0.10 ,≦ 5.0 | 410~510 | ≧ 12 | ≧ 0.10 ,≦ 5.0 | 120~180 | |

| H | ≧ 0.10 ,≦ 5.0 | 490~590 | ≧ 7 | ≧ 0.10 ,≦ 5.0 | 150~200 | |

| EH | ≧ 0.10 ,< 0.20 | 570~660 | - | ≧ 0.05 ,≦ 5.0 | 170~220 | |

| ≧ 0.20 ,≦ 5.0 | ≧ 3 | |||||

| SH | ≧ 0.10 ,≦ 5.0 | ≧ 640 | - | ≧ 0.05 ,≦ 5.0 | ≧ 200 | |

| C5102 | O | ≧ 0.10 ,≦ 5.0 | ≧ 305 | ≧ 40 | - | - |

| 1/4H | ≧ 0.10 ,≦ 5.0 | 375~470 | ≧ 28 | ≧ 0.10 ,≦ 5.0 | 90~160 | |

| 1/2H | ≧ 0.10 ,≦ 5.0 | 470~570 | ≧ 15 | ≧ 0.10 ,≦ 5.0 | 130~190 | |

| H | ≧ 0.10 ,≦ 5.0 | 570~665 | ≧ 7 | ≧ 0.10 ,≦ 5.0 | 170~220 | |

| EH | ≧ 0.10 ,< 0.20 | 620~710 | - | ≧ 0.05 ,≦ 5.0 | 190~230 | |

| ≧ 0.20 ,≦ 5.0 | ≧ 4 | |||||

| SH | ≧ 0.10 ,≦ 5.0 | ≧ 660 | - | ≧ 0.05 ,≦ 5.0 | ≧ 200 | |

| C5191 | O | ≧ 0.10 ,≦ 5.0 | ≧ 315 | ≧ 42 | - | - |

| 1/4H | ≧ 0.10 ,≦ 5.0 | 390~510 | ≧ 35 | ≧ 0.10 ,≦ 5.0 | 100~160 | |

| 1/2H | ≧ 0.10 ,≦ 5.0 | 490~610 | ≧ 20 | ≧ 0.10 ,≦ 5.0 | 150~205 | |

| H | ≧ 0.10 ,≦ 5.0 | 590~685 | ≧ 8 | ≧ 0.10 ,≦ 5.0 | 180~230 | |

| EH | ≧ 0.10 ,< 0.20 | 635~720 | - | ≧ 0.05 ,≦ 5.0 | 200~240 | |

| ≧ 0.20 ,≦ 5.0 | ≧ 5 | |||||

| SH | ≧ 0.10 ,≦ 5.0 | ≧ 690 | - | ≧ 0.05 ,≦ 5.0 | ≧ 210 | |

| C5212 | O | ≧ 0.10 ,≦ 5.0 | ≧ 345 | ≧ 45 | - | - |

| 1/4H | ≧ 0.10 ,≦ 5.0 | 390~510 | ≧ 40 | ≧ 0.10 ,≦ 5.0 | 100~160 | |

| 1/2H | ≧ 0.10 ,≦ 5.0 | 490~610 | ≧ 30 | ≧ 0.10 ,≦ 5.0 | 150~205 | |

| H | ≧ 0.10 ,≦ 5.0 | 590~705 | ≧ 12 | ≧ 0.10 ,≦ 5.0 | 180~235 | |

| EH | ≧ 0.10 ,< 0.20 | ≧ 685 | - | ≧ 0.05 ,≦ 5.0 | ≧ 210 | |

| ≧ 0.20 ,≦ 5.0 | ≧ 5 | |||||

厚度公差

C5050・HRD200・C5111・C5102・C5191・C5212(磷青铜)

单位:mm

备注:以上规格部分引用自JIS H3110。

当公差仅为(+)或仅为(-)时,数值为表格数值的2倍。

单位:mm

| 厚度 | 原田管理实绩 | 公差范围(宽度) | ||

|---|---|---|---|---|

| ≦ 400 | ||||

| ≧ 0.05 | ≦ 0.08 | ±0.002 | ±0.005 | |

| > 0.08 | ≦ 0.15 | ±0.005 | ±0.008 | |

| > 0.15 | ≦ 0.25 | ±0.007 | ±0.013 | |

| > 0.25 | ≦ 0.4 | ±0.010 | ±0.018 | |

| > 0.4 | ≦ 0.55 | ±0.012 | ±0.020 | |

| > 0.55 | ≦ 0.7 | ±0.015 | ±0.025 | |

| > 0.7 | ≦ 0.9 | ±0.020 | ±0.030 | |

| > 0.9 | ≦ 1.2 | ±0.025 | ±0.035 | |

弹片用磷青铜板及卷材

※如欲了解材料化学成分、机械特性,厚度规格及标准外规格等信息,请联系我们。

物理特性

| 型号 | (单位) | C5210 | C5240 |

|---|---|---|---|

| 比重 | - | 8.80 | 8.78 |

| 线膨胀系数 | 10-6 /K | 18.2 | 18.4 |

| 热传导率 | W/m・K | 63 | 50 |

| 导电率 | %IACS | 12 | 10 |

| 比热 | J/Kg・K | 377 | 375 |

| 纵向弹性系数(张力) | kN/m㎡ | 110 | 105 |

化学成分

| 型号 | 化学成分(%) | |||||

|---|---|---|---|---|---|---|

| Sn | P | Fe | Pb | Zn | Cu+Sn+P | |

| C5210 | 7.0~9.0 | 0.03~0.35 | ≦ 0.10 | ≦ 0.02 | ≦ 0.20 | ≧ 99.5 |

| C5240 | 9.0~11.00 | 0.03~0.35 | ≦ 0.10 | ≦ 0.02 | ≦ 0.20 | ≧ 99.5 |

机械特性

| 型号 | 材质 | 抗拉测试 | 弹簧极限值 | 硬度测试 | |||||

|---|---|---|---|---|---|---|---|---|---|

| 厚度 mm |

抗拉强度 N/m㎡ |

屈服强度 N/m㎡ |

延展率 % |

厚度 mm |

弹簧极限值 (Kb0.1) N/m㎡ |

厚度 mm |

硬度 HV※1 |

||

| C5210 | 1/2H | ≧ 0.10 ≦ 1.6 |

470~610 | ≧ 260 | ≧ 27 | ≧ 0.15 ≦ 1.6 |

≧ 245 | ≧ 0.10 ≦ 1.6 |

140~205 |

| H | ≧ 0.10 ≦ 1.6 |

590~705 | ≧ 450 | ≧ 20 | ≧ 0.15 ≦ 1.6 |

≧ 390 | ≧ 0.10 ≦ 1.6 |

185~235 | |

| EH | ≧ 0.10 ≦ 1.2 |

685~785 | ≧ 580 | ≧ 11 | ≧ 0.15 ≦ 1.6 |

≧ 460 | ≧ 0.10 ≦ 1.2 |

210~260 | |

| SH | ≧ 0.10 ≦ 1.2 |

735~835 | ≧ 640 | ≧ 9 | ≧ 0.15 ≦ 1.6 |

≧ 510 | ≧ 0.10 ≦ 1.2 |

230~270 | |

| ESH | ≧ 0.10 ≦ 0.40 |

770~885 | ≧ 690 | ≧ 5 | ≧ 0.15 ≦ 1.6 |

≧ 560 | ≧ 0.10 ≦ 0.4 |

245~285 | |

| C5240 | H | ≧ 0.10 ≦ 1.6 |

650~750 | ≧ 510 | ≧ 11 | ≧ 0.15 ≦ 1.6 |

≧ 430 | ≧ 0.10 ≦ 1.6 |

200~240 |

| EH | ≧ 0.10 ≦ 0.80 |

750~850 | ≧ 630 | ≧ 9 | ≧ 0.15 ≦ 1.6 |

≧ 510 | ≧ 0.10 ≦ 0.8 |

230~270 | |

| SH | ≧ 0.10 ≦ 0.40 |

850~950 | ≧ 750 | ≧ 5 | ≧ 0.15 ≦ 1.6 |

≧ 570 | ≧ 0.10 ≦ 0.40 |

250~300 | |

| ESH | ≧ 0.10 ≦ 0.40 |

≧ 950 | ≧ 870 | - | ≧ 0.15 ≦ 1.6 |

≧ 630 | ≧ 0.10 ≦ 0.40 |

≧ 270 | |

| XSH | ≧ 0.10 ≦ 0.40 |

≧ 1000 | ≧ 930 | - | ≧ 0.15 ≦ 1.6 |

≧ 700 | ≧ 0.10 ≦ 0.40 |

≧ 290 | |

厚度公差

C5210・C5240

单位:mm

单位:mm

| 厚度 | 原田管理实绩 | 公差范围(宽度) | ||

|---|---|---|---|---|

| ≦ 400 | ||||

| ≧ 0.05 | ≦ 0.08 | ±0.002 | ±0.005 | |

| > 0.08 | ≦ 0.15 | ±0.005 | ±0.008 | |

| > 0.15 | ≦ 0.25 | ±0.007 | ±0.013 | |

| > 0.25 | ≦ 0.4 | ±0.010 | ±0.018 | |

| > 0.4 | ≦ 0.55 | ±0.012 | ±0.020 | |

| > 0.55 | ≦ 0.7 | ±0.015 | ±0.025 | |

| > 0.7 | ≦ 0.9 | ±0.020 | ±0.030 | |

| > 0.9 | ≦ 1.2 | ±0.025 | ±0.035 | |

高性能磷青铜HQ系列

随着电子机械和零部件的小型化、轻薄化,要求磷青铜具备更高的强度和精度。

基于市场需求,本公司在原有的产品系列基础上开发了拥有高折弯性的「HQ」系列。

物理特性

HQ系列是对加工过程实施控制,从而提高机械特性的磷青铜,与以往的磷青铜合金成分相同,保持了原有的物理特性。

| 型号 | (单位) | C5191 | C5210 | C5240 |

|---|---|---|---|---|

| 比重 | - | 8.82 | 8.80 | 8.78 |

| 线膨胀系数 | 10-6 /K | 18.2 | 18.2 | 18.4 |

| 热传导率 | W/m・K | 67 | 63 | 50 |

| 导电率 | %IACS | 14 | 12 | 10 |

| 比热 | J/Kg・K | 375 | 377 | 375 |

| 纵向弹性系数(张力) | kN/m㎡ | 115 | 110 | 105 |

化学成分

【原田管理标准】化学成分和普通磷青铜一致,同时利用我司是磷青铜专业制造商的优势,对杂质进行更严格的管控。

| 式样 Spec. | Sn | P | Pb | Zn | Fe | Cu+Sn+P |

|---|---|---|---|---|---|---|

| C5191 | 5.5~7.0 | 0.03~0.20 | 0.01max | 0.01max | 0.01max | 99.8min |

| C5210 | 7.0~9.0 | 0.03~0.20 | 0.01max | 0.01max | 0.01max | 99.8min |

| C5240 | 9.0~11.0 | 0.04~0.20 | 0.01max | 0.01max | 0.01max | 99.8min |

| JIS标准 | ― | 0.03~0.35 | 0.02max | 0.20max | 0.10max | 99.5min |

产品尺寸

下表的材质、厚度皆以HQ材为例。如需确认更多材料规格,请联系我们。

| 型号 | 产品厚度 | 材质 | ||||

|---|---|---|---|---|---|---|

| H | EH | SH | ESH | XSH | ||

| C5191HQ | 0.05~0.30mm | ○ | ○ | ○ | ― | ― |

| C5210HQ | ○ | ○ | ○ | ○ | ○ | |

| C5240HQ | ○ | ○ | ○ | ○ | ○ | |

机械特性

HQ、一般材都为代表值

备注:以上规格部分引用自JIS H3130。适用厚度范围为0.05mm以上,0.3mm以下。

※因JIS H3130(2018)无规定,数据为原田内部标准。

| 型号 | 材质 | 类别 | 抗拉强度N/m㎡ | 屈服强度N/m㎡ | 延展率% | 硬度 HV | 弹簧极限值N/m㎡ |

|---|---|---|---|---|---|---|---|

| C5191 | H | JIS标准 | 590~685 | - | 8min | 180~230 | - |

| HQ | 630 | 614 | 22.6 | 203 | - | ||

| 一般材 | 620 | 600 | 17.6 | 202 | - | ||

| EH | JIS标准 | 635~720 | - | 5min | 200~240 | - | |

| HQ | 699 | 697 | 13.7 | 214 | - | ||

| 一般材 | 690 | 662 | 11.0 | 213 | - | ||

| SH | JIS标准 | 690min | - | - | 210min | - | |

| HQ | 744 | 739 | 12.7 | 222 | - | ||

| 一般材 | 725 | 710 | 8.3 | 216 | - | ||

| C5210 | H | JIS标准 | 590~705 | 450min | 20min | 185~235 | 390min |

| HQ | 616 | 569 | 35.3 | 197 | 469 | ||

| 一般材 | 615 | 549 | 28.6 | 193 | 462 | ||

| EH | JIS标准 | 685~785 | 580min | 11min | 210~260 | 460min | |

| HQ | 721 | 694 | 23.2 | 229 | 563 | ||

| 一般材 | 724 | 684 | 17.0 | 228 | 554 | ||

| SH | JIS标准 | 735~835 | 640min | 9min | 230~270 | 510min | |

| HQ | 778 | 773 | 13.3 | 242 | 632 | ||

| 一般材 | 771 | 756 | 11.4 | 240 | 627 | ||

| ESH | JIS标准 | 770~885 | 690min | 5min | 245~285 | 560min | |

| HQ | 845 | 834 | 9.3 | 258 | 648 | ||

| 一般材 | - | - | - | - | - | ||

XSH ※ |

JIS标准 | 835~1000 | - | 1min | - | 630min | |

| HQ | 979 | 968 | 2.1 | 285 | 706 | ||

| 一般材 | - | - | - | - | - | ||

| C5240 | H | JIS标准 | 650~750 | 510min | 11min | 200~240 | 430min |

| HQ | 693 | 657 | 25.6 | 223 | 558 | ||

| EH | JIS标准 | 750~850 | 630min | 9min | 230~270 | 510min | |

| HQ | 800 | 783 | 15.3 | 245 | 585 | ||

| SH | JIS标准 | 850~950 | 750min | 5min | 250~300 | 570min | |

| HQ | 890 | 877 | 9.2 | 267 | 661 | ||

| ESH | JIS标准 | 950min | 870min | - | 270min | 630min | |

| HQ | 1000 | 988 | 2.4 | 285 | 718 | ||

| XSH | JIS标准 | 1000min | 930min | - | 290min | 700min | |

| HQ | 1058 | 1044 | 2.0 | 305 | 883 |

厚度公差

C5240

单位:mm

备注:以上规格部分引用自JIS H3130。

单位:mm

| 厚度 | 原田管理实绩 | JIS标准 |

|---|---|---|

| ≧ 0.05 ,≦ 0.08 | ±0.002 | ±0.005 |

| > 0.08 ,≦ 0.15 | ±0.005 | ±0.008 |

| > 0.15 ,≦ 0.25 | ±0.007 | ±0.013 |

| > 0.25 ,≦ 0.30 | ±0.008 | ±0.018 |

超高强度磷青铜 HC5270

为了满足对更高强度磷青铜的强烈需求,我们通过不断研究产品特性和生产工艺,成功开发了锡含量达12%的超高强度磷青铜「HC5270」。

今后,我们将继续通过供应符合客户需求的产品来回应客户的信赖。

物理特性

| 型号 | (单位) | HC5270 |

|---|---|---|

| 比重 | - | 8.75 |

| 线膨胀系数 | 10-6 /K | 18.4 |

| 热传导率 | W/m・K | 41 |

| 导电率 | %IACS | 8.5 |

| 比热 | J/Kg・K | 368 |

| 纵向弹性系数(张力) | kN/m㎡ | 103 |

| 泊松比 | - | 0.33 |

化学成分

【原田管理标准】我司充分利用磷青铜专业制造商的优势,对杂质进行更严格的管控。

| 化学成分(%) | |||||

|---|---|---|---|---|---|

| Sn | P | Pb | Zn | Fe | Cu+Sn+P |

| 11.0~13.0 | 0.03~0.20 | 0.01max | 0.01max | 0.01max | 99.8min |

产品尺寸

状态和厚度如下表所示。如需确认更多材料规格,请联系我们。

| 产品厚度 | 材质 | ||||

|---|---|---|---|---|---|

| H | EH | SH | ESH | XSH | |

| 0.05~0.20mm | ○ | ○ | - | - | - |

| 0.05~0.15mm | - | - | ○ | ○ | ○ |

机械特性

HC5270为代表例。

| 材质 | 类别 | 抗拉强度N/m㎡ | 屈服强度N/m㎡ | 延展率% | 硬度 HV |

|---|---|---|---|---|---|

| H | 标准 | 750~850 | 620min | 9min | 230~270 |

| HC5270 | 812 | 765 | 15.5 | 255 | |

| EH | 标准 | 850~950 | 740min | 5min | 250~290 |

| HC5270 | 895 | 842 | 8.7 | 267 | |

| SH | 标准 | 950~1050 | 860min | 1min | 270~310 |

| HC5270 | 1001 | 949 | 2.3 | 291 | |

| ESH | 标准 | 1050min | 980min | - | 285min |

| HC5270 | 1109 | 1075 | 1.5 | 307 | |

| XSH | 标准 | 1140min | 1060min | - | 310min |

| HC5270 | 1213 | 1167 | 1.5 | 354 |

厚度公差

单位:㎜

| 厚度 | 原田管理实绩 | JIS标准 |

|---|---|---|

| ≧ 0.05 ,≦ 0.08 | ±0.002 | ±0.005 |

| > 0.08 ,≦ 0.15 | ±0.005 | ±0.008 |

| > 0.15 ,≦ 0.20 | ±0.007 | ±0.013 |