Products

Phosphor Bronze Plates and Strips

*Please contact us if you have any specific requests regarding chemical compositions, mechanical properties, and thicknesses.

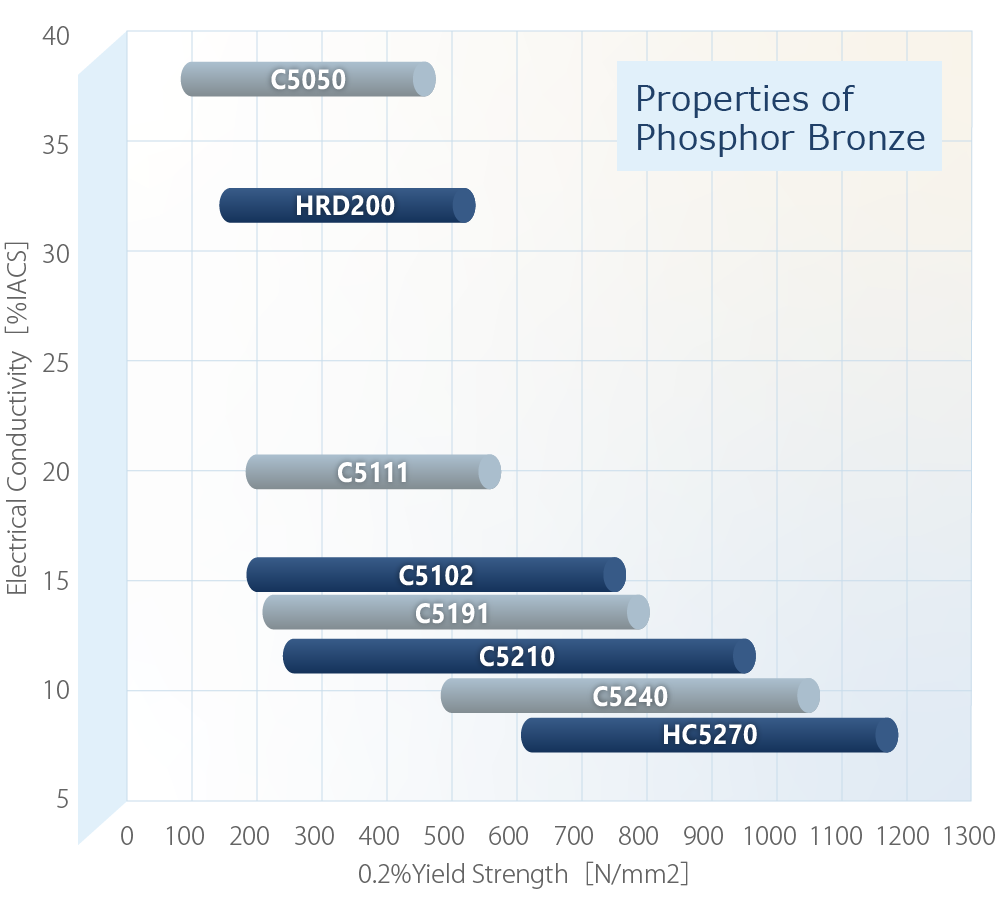

Physical Properties

| Alloy Number | (unit) | C5050 | HRD200 | C5111 | C5102 | C5191 | C5212 |

|---|---|---|---|---|---|---|---|

| Specific Gravity | - | 8.89 | 8.87 | 8.86 | 8.86 | 8.82 | 8.80 |

| Coefficient of Thermal Expansion | 10-6 /K | 17.8 | 16.5 | 17.8 | 17.8 | 18.2 | 18.2 |

| Thermal Conductivity | W/m・K | 205 | 152 | 84 | 71 | 67 | 63 |

| Electrical Conductivity | %IACS | 38 | 32 | 20 | 15 | 14 | 12 |

| Specific Heat | J/Kg・K | 377 | 377 | 377 | 377 | 375 | 377 |

| Modulus of Elasticity (Tension) | kN/m㎡ | 118 | 122 | 110 | 110 | 115 | 110 |

Chemical Composition

| Alloy No. | Chemical Composition(%) | |||||

|---|---|---|---|---|---|---|

| Sn | P | Fe | Pb | Zn | Cu+Sn+P | |

| C5050 | 1.0~1.7 | ≦ 0.15 | ≦ 0.10 | ≦ 0.02 | ≦ 0.20 | ≧ 99.5 | HRD200 | 1.7~2.3 | ≦ 0.15 |

| C5111 | 3.5~4.5 | 0.03~0.35 | ||||

| C5102 | 4.5~5.5 | |||||

| C5191 | 5.5~7.0 | |||||

| C5212 | 7.0~9.0 | |||||

Mechanical Properties

| Alloy No. | Temper | Tension Test | Hardness Test | |||

|---|---|---|---|---|---|---|

| Thickness Category ㎜ |

Tensile Strength N/m㎡ |

Elongation % |

Thickness Category ㎜ |

Vickers Hardness HV*1 |

||

| C5050 | O | ≧ 0.10 ,≦ 5.0 | ≧ 240 | ≧ 40 | - | - |

| 1/4H | ≧ 0.10 ,≦ 5.0 | 240~330 | ≧ 30 | ≧ 0.15 ,≦ 5.0 | 60~120 | |

| 1/2H | ≧ 0.10 ,≦ 5.0 | 330~450 | ≧ 10 | ≧ 0.10 ,≦ 5.0 | 90~155 | |

| H | ≧ 0.10 ,≦ 5.0 | 390~500 | ≧ 3 | ≧ 0.10 ,≦ 5.0 | 120~165 | |

| EH | ≧ 0.10 ,≦ 5.0 | ≧ 460 | - | ≧ 0.05 ,≦ 5.0 | ≧ 140 | |

| HRD200 | O | ≧ 0.10 ,≦ 5.0 | ≧ 300 | ≧ 30 | ≧ 0.10 ,≦ 5.0 | 70~115 |

| 1/2H | ≧ 0.10 ,≦ 5.0 | 400~500 | ≧ 10 | ≧ 0.10 ,≦ 5.0 | 125~165 | |

| H | ≧ 0.10 ,≦ 5.0 | 450~550 | ≧ 5 | ≧ 0.10 ,≦ 5.0 | 150~185 | |

| EH | ≧ 0.10 ,≦ 5.0 | 500~600 | ≧ 2 | ≧ 0.10 ,≦ 5.0 | 175~205 | |

| SH | ≧ 0.10 ,≦ 5.0 | 600~700 | - | ≧ 0.10 ,≦ 5.0 | 185~215 | |

| C5111 | O | ≧ 0.10 ,≦ 5.0 | ≧ 295 | ≧ 38 | - | - |

| 1/4H | ≧ 0.10 ,≦ 5.0 | 345~440 | ≧ 25 | ≧ 0.15 ,≦ 5.0 | 80~150 | |

| 1/2H | ≧ 0.10 ,≦ 5.0 | 410~510 | ≧ 12 | ≧ 0.10 ,≦ 5.0 | 120~180 | |

| H | ≧ 0.10 ,≦ 5.0 | 490~590 | ≧ 7 | ≧ 0.10 ,≦ 5.0 | 150~200 | |

| EH | ≧ 0.10 ,< 0.20 | 570~660 | - | ≧ 0.05 ,≦ 5.0 | 170~220 | |

| ≧ 0.20 ,≦ 5.0 | ≧ 3 | |||||

| SH | ≧ 0.10 ,≦ 5.0 | ≧ 640 | - | ≧ 0.05 ,≦ 5.0 | ≧ 200 | |

| C5102 | O | ≧ 0.10 ,≦ 5.0 | ≧ 305 | ≧ 40 | - | - |

| 1/4H | ≧ 0.10 ,≦ 5.0 | 375~470 | ≧ 28 | ≧ 0.10 ,≦ 5.0 | 90~160 | |

| 1/2H | ≧ 0.10 ,≦ 5.0 | 470~570 | ≧ 15 | ≧ 0.10 ,≦ 5.0 | 130~190 | |

| H | ≧ 0.10 ,≦ 5.0 | 570~665 | ≧ 7 | ≧ 0.10 ,≦ 5.0 | 170~220 | |

| EH | ≧ 0.10 ,< 0.20 | 620~710 | - | ≧ 0.05 ,≦ 5.0 | 190~230 | |

| ≧ 0.20 ,≦ 5.0 | ≧ 4 | |||||

| SH | ≧ 0.10 ,≦ 5.0 | ≧ 660 | - | ≧ 0.05 ,≦ 5.0 | ≧ 200 | |

| C5191 | O | ≧ 0.10 ,≦ 5.0 | ≧ 315 | ≧ 42 | - | - |

| 1/4H | ≧ 0.10 ,≦ 5.0 | 390~510 | ≧ 35 | ≧ 0.10 ,≦ 5.0 | 100~160 | |

| 1/2H | ≧ 0.10 ,≦ 5.0 | 490~610 | ≧ 20 | ≧ 0.10 ,≦ 5.0 | 150~205 | |

| H | ≧ 0.10 ,≦ 5.0 | 590~685 | ≧ 8 | ≧ 0.10 ,≦ 5.0 | 180~230 | |

| EH | ≧ 0.10 ,< 0.20 | 635~720 | - | ≧ 0.05 ,≦ 5.0 | 200~240 | |

| ≧ 0.20 ,≦ 5.0 | ≧ 5 | |||||

| SH | ≧ 0.10 ,≦ 5.0 | ≧ 690 | - | ≧ 0.05 ,≦ 5.0 | ≧ 210 | |

| C5212 | O | ≧ 0.10 ,≦ 5.0 | ≧ 345 | ≧ 45 | - | - |

| 1/4H | ≧ 0.10 ,≦ 5.0 | 390~510 | ≧ 40 | ≧ 0.10 ,≦ 5.0 | 100~160 | |

| 1/2H | ≧ 0.10 ,≦ 5.0 | 490~610 | ≧ 30 | ≧ 0.10 ,≦ 5.0 | 150~205 | |

| H | ≧ 0.10 ,≦ 5.0 | 590~705 | ≧ 12 | ≧ 0.10 ,≦ 5.0 | 180~235 | |

| EH | ≧ 0.10 ,< 0.20 | ≧ 685 | - | ≧ 0.05 ,≦ 5.0 | ≧ 210 | |

| ≧ 0.20 ,≦ 5.0 | ≧ 5 | |||||

*1 Minimum test force is 1.961N

Thickness Tolerances

Unit:mm

| Thickness | Our Achievements | Tolerance (width) | ||

|---|---|---|---|---|

| ≦ 400 | ||||

| ≧ 0.05 | ≦ 0.08 | ±0.002 | ±0.005 | |

| > 0.08 | ≦ 0.15 | ±0.005 | ±0.008 | |

| > 0.15 | ≦ 0.25 | ±0.007 | ±0.013 | |

| > 0.25 | ≦ 0.4 | ±0.010 | ±0.018 | |

| > 0.4 | ≦ 0.55 | ±0.012 | ±0.020 | |

| > 0.55 | ≦ 0.7 | ±0.015 | ±0.025 | |

| > 0.7 | ≦ 0.9 | ±0.020 | ±0.030 | |

| > 0.9 | ≦ 1.2 | ±0.025 | ±0.035 | |

Phosphor Bronze Plates and Strips for Springs

*Please contact us if you have any specific requests regarding chemical composition, mechanical properties, and thicknesses.

Physical Properties

| Alloy Number | (unit) | C5210 | C5240 |

|---|---|---|---|

| Specific Gravity | - | 8.80 | 8.78 |

| Coefficient of Thermal Expansion | 10-6 /K | 18.2 | 18.4 |

| Thermal Conductivity | W/m・K | 63 | 50 |

| Electrical Conductivity | %IACS | 12 | 10 |

| Specific Heat | J/Kg・K | 377 | 375 |

| Modulus of Elasticity(Tension) | kN/m㎡ | 110 | 105 |

Chemical Composition

| Alloy No. | Chemical Composition(%) | |||||

|---|---|---|---|---|---|---|

| Sn | P | Fe | Pb | Zn | Cu+Sn+P | |

| C5210 | 7.0~9.0 | 0.03~0.35 | ≦ 0.10 | ≦ 0.02 | ≦ 0.20 | ≧ 99.5 |

| C5240 | 9.0~11.00 | 0.03~0.35 | ≦ 0.10 | ≦ 0.02 | ≦ 0.20 | ≧ 99.5 |

Mechanical Properties

| Alloy No. | Temper | Tension Test | Elastic Limit Test of Spring | Hardness Test | |||||

|---|---|---|---|---|---|---|---|---|---|

| Thickness Category mm |

Tensile Strength N/m㎡ |

0.2% Yield Strength N/m㎡ |

Elongation % |

Thickness Category mm |

Elastic Limit of Spring (Kb0.1) N/m㎡ |

Thickness Category mm |

Vickers Hardness HV*1 |

||

| C5210 | 1/2H | ≧ 0.10 ≦ 1.6 |

470~610 | ≧ 260 | ≧ 27 | ≧ 0.15 ≦ 1.6 |

≧ 245 | ≧ 0.10 ≦ 1.6 |

140~205 |

| H | ≧ 0.10 ≦ 1.6 |

590~705 | ≧ 450 | ≧ 20 | ≧ 0.15 ≦ 1.6 |

≧ 390 | ≧ 0.10 ≦ 1.6 |

185~235 | |

| EH | ≧ 0.10 ≦ 1.2 |

685~785 | ≧ 580 | ≧ 11 | ≧ 0.15 ≦ 1.6 |

≧ 460 | ≧ 0.10 ≦ 1.2 |

210~260 | |

| SH | ≧ 0.10 ≦ 1.2 |

735~835 | ≧ 640 | ≧ 9 | ≧ 0.15 ≦ 1.6 |

≧ 510 | ≧ 0.10 ≦ 1.2 |

230~270 | |

| ESH | ≧ 0.10 ≦ 0.40 |

770~885 | ≧ 690 | ≧ 5 | ≧ 0.15 ≦ 1.6 |

≧ 560 | ≧ 0.10 ≦ 0.4 |

245~285 | |

| C5240 | H | ≧ 0.10 ≦ 1.6 |

650~750 | ≧ 510 | ≧ 11 | ≧ 0.15 ≦ 1.6 |

≧ 430 | ≧ 0.10 ≦ 1.6 |

200~240 |

| EH | ≧ 0.10 ≦ 0.80 |

750~850 | ≧ 630 | ≧ 9 | ≧ 0.15 ≦ 1.6 |

≧ 510 | ≧ 0.10 ≦ 0.8 |

230~270 | |

| SH | ≧ 0.10 ≦ 0.40 |

850~950 | ≧ 750 | ≧ 5 | ≧ 0.15 ≦ 1.6 |

≧ 570 | ≧ 0.10 ≦ 0.40 |

250~300 | |

| ESH | ≧ 0.10 ≦ 0.40 |

≧ 950 | ≧ 870 | - | ≧ 0.15 ≦ 1.6 |

≧ 630 | ≧ 0.10 ≦ 0.40 |

≧ 270 | |

| XSH | ≧ 0.10 ≦ 0.40 |

≧ 1000 | ≧ 930 | - | ≧ 0.15 ≦ 1.6 |

≧ 700 | ≧ 0.10 ≦ 0.40 |

≧ 290 | |

*1 Minimum test force is 1.961N

Thickness Tolerances

Unit:mm

| Thickness | Our Achievements | Tolerance (width) | |

|---|---|---|---|

| ≦ 400 | |||

| ≧ 0.05 | ≦ 0.08 | ±0.002 | ±0.005 |

| > 0.08 | ≦ 0.15 | ±0.005 | ±0.008 |

| > 0.15 | ≦ 0.25 | ±0.007 | ±0.013 |

| > 0.25 | ≦ 0.4 | ±0.010 | ±0.018 |

| > 0.4 | ≦ 0.55 | ±0.012 | ±0.020 |

| > 0.55 | ≦ 0.7 | ±0.015 | ±0.025 |

| > 0.7 | ≦ 0.9 | ±0.020 | ±0.030 |

| > 0.9 | ≦ 1.2 | ±0.025 | ±0.035 |

HQ Phosphor Bronze with High Strength and Bending Workability

As electronic devices and parts become smaller and thinner, the need for high strength and precision in the phosphor bronze as the base material also increases.

To meet these needs, we have established a production system for High Quality phosphor bronze with high bending workability (HQ series) in addition to our existing lineup.

Physical Properties

| Alloy Number | (unit) | C5191 | C5210 | C5240 |

|---|---|---|---|---|

| Specific Gravity | - | 8.82 | 8.80 | 8.78 |

| Linear Expansion Coefficient | 10-6 /K | 18.2 | 18.2 | 18.4 |

| Thermal Conductivity | W/m・K | 67 | 63 | 50 |

| Electrical Conductivity | %IACS | 14 | 12 | 10 |

| Specific Heat | J/Kg・K | 375 | 377 | 375 |

| Modulus of Elasticity(Tension) | kN/m㎡ | 115 | 110 | 105 |

Chemical Composition

| Specifications | Sn | P | Pb | Zn | Fe | Cu+Sn+P |

|---|---|---|---|---|---|---|

| C5191 | 5.5~7.0 | 0.03~0.20 | 0.01max | 0.01max | 0.01max | 99.8min |

| C5210 | 7.0~9.0 | 0.03~0.20 | 0.01max | 0.01max | 0.01max | 99.8min |

| C5240 | 9.0~11.0 | 0.04~0.20 | 0.01max | 0.01max | 0.01max | 99.8min |

| Standard | ― | 0.03~0.35 | 0.02max | 0.20max | 0.10max | 99.5min |

Product Size

| Type | Thickness | Temper | ||||

|---|---|---|---|---|---|---|

| H | EH | SH | ESH | XSH | ||

| C5191HQ | 0.05~0.30mm | ○ | ○ | ○ | ― | ― |

| C5210HQ | ○ | ○ | ○ | ○ | ○ | |

| C5240HQ | ○ | ○ | ○ | ○ | ○ | |

Mechanical Properties

| Alloy No. | Temper | Symbol | Tensile Strength N/m㎡ | 0.2% Yield Strength N/m㎡ | Elongation % | Hardness HV | Elastic Limit of Spring N/m㎡ |

|---|---|---|---|---|---|---|---|

| C5191 | H | Standard | 590~685 | - | 8min | 180~230 | - |

| HQ | 630 | 614 | 22.6 | 203 | - | ||

| Harada’s average | 620 | 600 | 17.6 | 202 | - | ||

| EH | Standard | 635~720 | - | 5min | 200~240 | - | |

| HQ | 699 | 697 | 13.7 | 214 | - | ||

| Harada’s average | 690 | 662 | 11.0 | 213 | - | ||

| SH | Standard | 690min | - | - | 210min | - | |

| HQ | 744 | 739 | 12.7 | 222 | - | ||

| Harada’s average | 725 | 710 | 8.3 | 216 | - | ||

| C5210 | H | Standard | 590~705 | 450min | 20min | 185~235 | 390min |

| HQ | 616 | 569 | 35.3 | 197 | 469 | ||

| Harada’s average | 615 | 549 | 28.6 | 193 | 462 | ||

| EH | Standard | 685~785 | 580min | 11min | 210~260 | 460min | |

| HQ | 721 | 694 | 23.2 | 229 | 563 | ||

| Harada’s average | 724 | 684 | 17.0 | 228 | 554 | ||

| SH | Standard | 735~835 | 640min | 9min | 230~270 | 510min | |

| HQ | 778 | 773 | 13.3 | 242 | 632 | ||

| Harada’s average | 771 | 756 | 11.4 | 240 | 627 | ||

| ESH | Standard | 770~885 | 690min | 5min | 245~285 | 560min | |

| HQ | 845 | 834 | 9.3 | 258 | 648 | ||

| Harada’s average | - | - | - | - | - | ||

XSH * |

Standard | 835~1000 | - | 1min | - | 630min | |

| HQ | 979 | 968 | 2.1 | 285 | 706 | ||

| Harada’s average | - | - | - | - | - | ||

| C5240 | H | Standard | 650~750 | 510min | 11min | 200~240 | 430min |

| HQ | 693 | 657 | 25.6 | 223 | 558 | ||

| EH | Standard | 750~850 | 630min | 9min | 230~270 | 510min | |

| HQ | 800 | 783 | 15.3 | 245 | 585 | ||

| SH | Standard | 850~950 | 750min | 5min | 250~300 | 570min | |

| HQ | 890 | 877 | 9.2 | 267 | 661 | ||

| ESH | Standard | 950min | 870min | - | 270min | 630min | |

| HQ | 1000 | 988 | 2.4 | 285 | 718 | ||

| XSH | Standard | 1000min | 930min | - | 290min | 700min | |

| HQ | 1058 | 1044 | 2.0 | 305 | 883 |

*Internal standards are shown because the products are not standardized by JIS H3130(2018)

Thickness Tolerances

Unit:mm

| Thickness | Our Achievements | Standard |

|---|---|---|

| ≧ 0.05㎜ ,≦ 0.08㎜ | ±0.002㎜ | ±0.005㎜ |

| > 0.08㎜ ,≦ 0.15㎜ | ±0.005㎜ | ±0.008㎜ |

| > 0.15㎜ ,≦ 0.25㎜ | ±0.007㎜ | ±0.013㎜ |

| > 0.25㎜ ,≦ 0.30㎜ | ±0.008㎜ | ±0.018㎜ |

Super-High Strength Phosphor Bronze HC5270

In order to meet the high expectations for higher strength phosphor bronze than ever before, we have carried out research and development of product characteristics and developed the ultra high strength phosphor bronze “HC5270” with a higher tin content of 12%.

We will continue to work to earn the trust of our valued customers by supplying the products required.

Physical Properties

| Alloy Number | (unit) | HC5270 |

|---|---|---|

| Specific Gravity | - | 8.75 |

| Coefficient of Thermal Expansion | 10-6 /K | 18.4 |

| Thermal Conductivity | W/m・K | 41 |

| Electrical Conductivity | %IACS | 8.5 |

| Specific Heat | J/Kg・K | 368 |

| Modulus of Elasticity(Tension) | kN/m㎡ | 103 |

| Poisson's ratio | ー | 0.33 |

Chemical Composition

| Chemical Composition(%) | |||||

|---|---|---|---|---|---|

| Sn | P | Pb | Zn | Fe | Cu+Sn+P |

| 11.0~13.0 | 0.03~0.20 | 0.01max | 0.01max | 0.01max | 99.8min |

Product Size

| Thickness | Temper | ||||

|---|---|---|---|---|---|

| H | EH | SH | ESH | XSH | |

| 0.05~0.20mm | ○ | ○ | - | - | - |

| 0.05~0.15mm | - | - | ○ | ○ | ○ |

Mechanical Properties

| Temper | Symbol | Tensile Strength N/m㎡ | 0.2% Yield Strength N/m㎡ | Elongation % | Hardness HV |

|---|---|---|---|---|---|

| H | Standard | 750~850 | 620min | 9min | 230~270 |

| HC5270 | 812 | 765 | 15.5 | 255 | |

| EH | Standard | 850~950 | 740min | 5min | 250~290 |

| HC5270 | 895 | 842 | 8.7 | 267 | |

| SH | Standard | 950~1050 | 860min | 1min | 270~310 |

| HC5270 | 1001 | 949 | 2.3 | 291 | |

| ESH | Standard | 1050min | 980min | ー | 285min |

| HC5270 | 1109 | 1075 | 1.5 | 307 | |

| XSH | Standard | 1140min | 1060min | ー | 310min |

| HC5270 | 1213 | 1167 | 1.5 | 354 |

Thickness Tolerances

| Thickness | Our Achievements | Standard |

|---|---|---|

| ≧ 0.05 ,≦ 0.08 | ±0.002 | ±0.005 |

| > 0.08 ,≦ 0.15 | ±0.005 | ±0.008 |

| > 0.15 ,≦ 0.20 | ±0.007 | ±0.013 |